DRONES at the service of YOUR TURBINES

At SupAirVision, we develop innovative tools and services to provide you with a precise and instantaneous view of the condition of your wind turbines. Discover our solutions tailored to your needs:

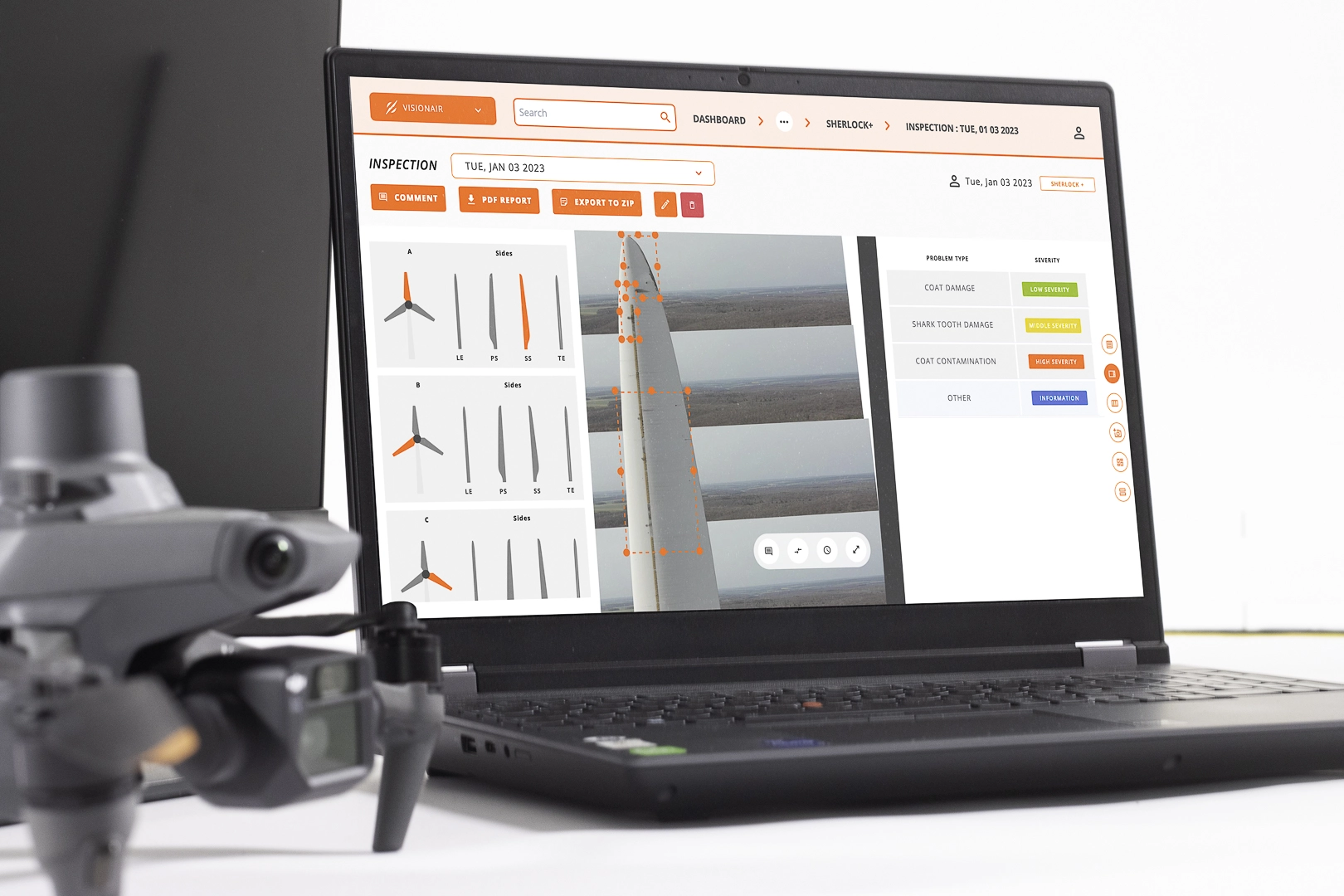

- VisionAir, a secure cloud to centralize and analyze all your inspection data.

- Sherlock, our visual inspection service by drone with two possible acquisition qualities and the ability to inspect without stopping the turbine.

- Volta, the world's first solution that assesses the integrity of the lightning protection system by drone, ensuring the continuity of the protection system.

- Clarity, our thermographic inspection solutions for detecting structural defects before they propagate to the surface.

OUR SUPPORT

COMMISSIONING

PERIODIC INSPECTION

END OF WARRANTY

DUE DILIGENCE

COMMISSIONING

Leverage the rapid action of our drones and the precision of our onboard sensors to ensure the reliability of the commissioning audit of your wind turbines. Our services guarantee that the assembly of the blades and rotor has not damaged the surface of the blades or the tower, thanks to high-quality photos covering 100% of the surface. The images are assembled and stored to create a reliable and exhaustive "zero state" on our secure cloud. Additionally, we minimize the risk of lightning damage by ensuring the proper functioning of the lightning protection system (LPS) and archiving the precise resistance values measured during commissioning.

PERIODIC INSPECTION

Reduce risks at the end of the warranty period and benefit from third-party advice with a detailed and thorough audit of the condition of your blades, by choosing the precision and quality of the drone and its onboard sensors. We take high-definition photos of all four faces of each blade, perform continuity tests of the lightning protection system by digital measurement, or diagnose internal defects through thermography. The precision and quality of the measurements performed by the drone ensure a reliable and accurate end-of-warranty condition of the assets. Based on our annotated and detailed inspection reports, make the best decision for the maintenance management of your blades and towers, whether it is to internalize, renew, or change the maintenance contract.

END OF WARRANTY

Reduce risks at the end of the warranty period and benefit from third-party advice with a detailed and thorough audit of the condition of your blades, by choosing the precision and quality of the drone and its onboard sensors. We take high-definition photos of all four faces of each blade, perform continuity tests of the lightning protection system by digital measurement, or diagnose internal defects through thermography. The precision and quality of the measurements performed by the drone ensure a reliable and accurate end-of-warranty condition of the assets. Resume operation or decide to extend the life and exploitation of your assets based on annotated and detailed inspection reports.

DUE DILIGENCE

Obtain a more precise view of the condition of your audited assets as part of a due diligence process, thanks to the precision and quality of the sensors onboard our drones: blade condition, lightning protection system level, tower condition, etc. We perform a visual audit with high-definition photos of all four sides of each blade, continuity tests of the lightning protection system by digital measurement, or diagnose internal defects through thermography. Benefit from the measurements performed by the drone to ensure a complete, reliable, and accurate due diligence. Make your investment decision based on annotated and detailed inspection reports, and enhance the value of your wind turbines in the second-hand market with quality photos and comprehensive reports.

Our latest news

Production Loss? NO MORE!

xSHERLOCK MOTION

Boost your productivity and efficiency with Sherlock Motion

.png)