Wind Turbine Inspection

INSPECT YOUR WIND TURBINES

Benefit from a smooth intervention process and the rapidity of SupAirVision tools to inspect your wind turbines regularly and more easily. The speed of inspection of the drone and of SupAirVision teams reduces the wind turbine downtime and increases the availability of your technicians. Visualise your blades with an ergonomic tool which helps you identify precisely the defects and damages, compare your reports with your previous inspections and follow the state of your wind turbines over time.

PRECISION

RAPIDITY

SECURITY

FULL SUPPORT

LIGHTNING PROTECTION SYSTEM (LPS) integrity

VISUAL INSPECTION

IN-DEPTH INSPECTION

Secure your wind turbines with Volta, the world’s first drone capable of quickly, reliably, and efficiently diagnosing discontinuities in your lightning protection system:

- Precise measure of the resistance of the lightning path and picture of the receptor

- Contact with the lightning receptor by drone

- Up to 10 wind turbines per day (30min per turbine)

- Assisted piloting system and data interpreted by an expert

- Innovative and patented technology, a world’s first

- Measurement of the resistance of the blades, the tower and the whole turbine autonomously with our wind turbine technicians or by renting the drones

HOW DOES IT WORK?

- Rotors stop control according to SupAirVision protocol

- Drone flight with assisted piloting

- Contact with the receptor and picture-taking

- Analysis and measurement by experts and identification of any irregularity

- Generation of reports on the VisionAir cloud

ASSOCIATED PRODUCTS

With Sherlock, obtain a complete diagnostic of the surface condition of your blades and towers through drone inspection. Gain access to high-quality images and leverage our expertise for quick, reliable, and efficient maintenance:

- Assisted and automated flight

- 100% autonomous interventions by our wind turbine technicians and drone pilots, or by your teams

- No mandatory blade pitch, 30min-1h per turbine (reduction of the downtime)

- Personalised offer with two levels of quality depending on your needs (20Mpx, 45Mpx)

- Safe inspection, with no human risks

- Detection of the finest defects (less than 1 mm diameter)

- Complete digitalisation of each blade and tower face

- Possible to rent the material with the automated inspection application

HOW DOES IT WORK?

- Rotors stop control according to SupAirVision protocol

- Automated flights and shots

- Transfer of the images to the VisionAir cloud

- Image-assembling for a complete view

- Identification of the defects (position, size, criticality)

- Automatic and customizable reports’ generation

- Automated transfer of the data in your CMMS from the VisionAir cloud thanks to our Application Programming Interface (API)

ASSOCIATED PRODUCTS

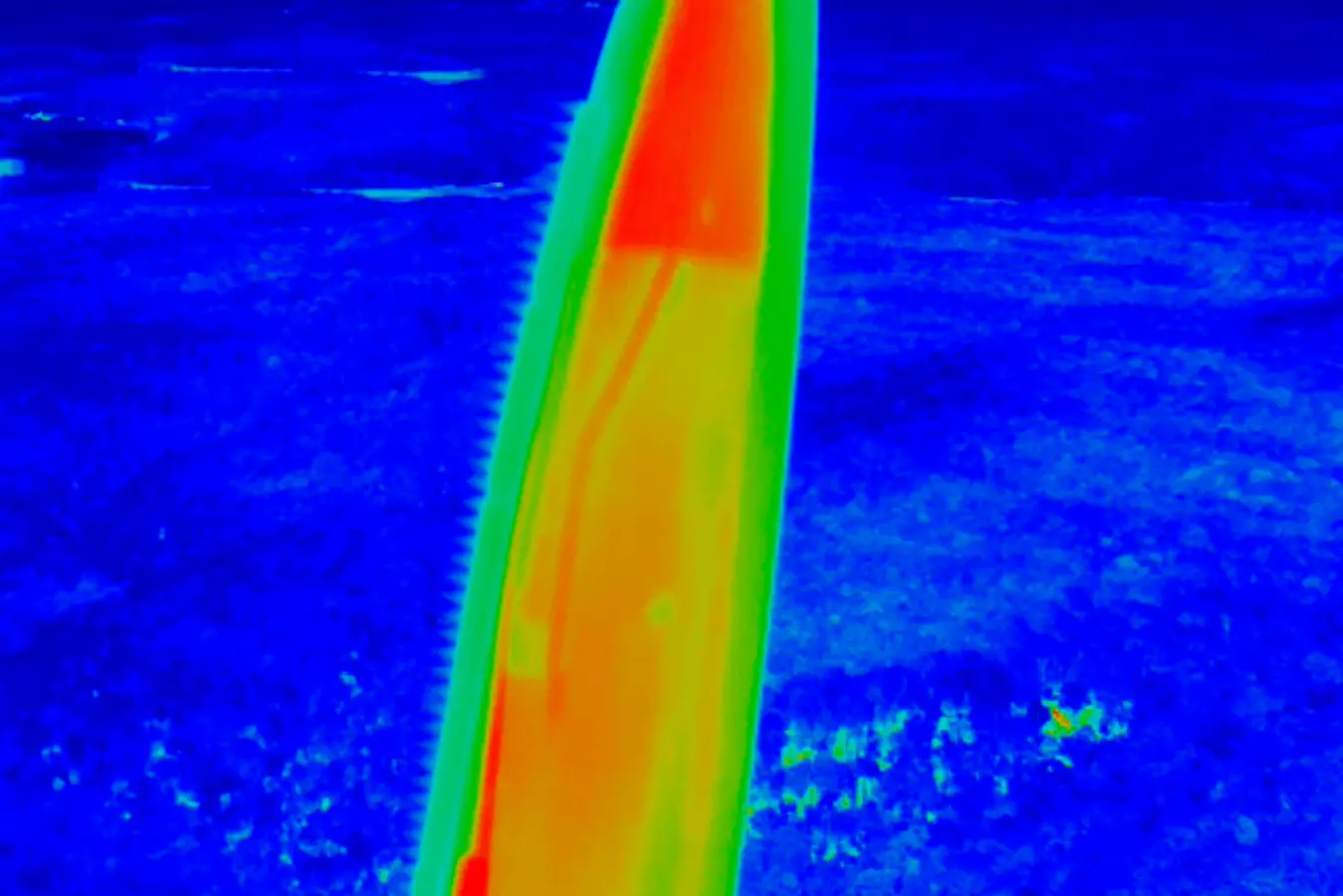

With Clarity, obtain a precise evaluation of the structural condition of your blades and towers through thermographic drone inspection. Benefit from our expertise for proactive and effective maintenance:

- Passive thermography by drone (SupAirVision protocol)

- Active thermography thanks to a laser system embarked on a lifting platform (patented system)

- Precise indication of the type of defect, its size and location (as well as its depth in case of an active thermography)

- Repairs costs divided by two thanks to the anticipated detection of damages

- Limitation of the risks of severe breakdowns thanks to the anticipation of repairs

- Facilitated follow-up of evolution of the defects

- Reproducible inspections

HOW DOES IT WORK (CLARITY PASSIF)?

- Rotors stop control according to SupAirVision protocol

- Flight by drone and thermal image-taking of each side of the blades

- Transfer of the images to the cloud

- Analysis of the images by SupAirVision experts and identification of damages

- Simultaneous viewing of thermal and visual images on the VisionAir cloud

- Generation of customizable reports and integration in VisionAir and/or in your CMMS

ASSOCIATED PRODUCTS

CENTRALIZE ALL OF THE INSPECTION DATA WITH VISIONAIR

Our VisionAir cloud platform allows you to view and annotate your blades and towers on a single ergonomic, secure, and accessible online platform. Track the evolution of defects from one inspection to another by linking defects on the platform and directly generate reports to better plan your maintenance. All your data is thus centralized, regardless of the technology used and the type of photos (rope access, telephoto lens, manual and automatic drone, etc.). If desired, you can also interface VisionAir with your management tools (CMMS) through our application programming interface (API).