OPERATIONAL MANAGEMENT

FACILITATE YOUR PLANNING

Benefit from the drones’ and SupAirVision teams’ rapidity of action - autonomous to stop the wind turbines - to regularly inspect your wind turbines in an efficient and secure way.

The operational flexibility of the drone and its work output enable you to make the most of the best weather conditions to run your inspections with your teams of pilots and that of SupAirVision.

A detailed vision of your turbines (blades and towers) enables you to make the right maintenance decisions, based on the annotations and the ranking of the defects made by our blade, tower and composite expert.

SIMPLICITY

PReCISION

RELIABILITY

OUR SOLUTIONS

ASSESSMENT OF THE DEFECTS

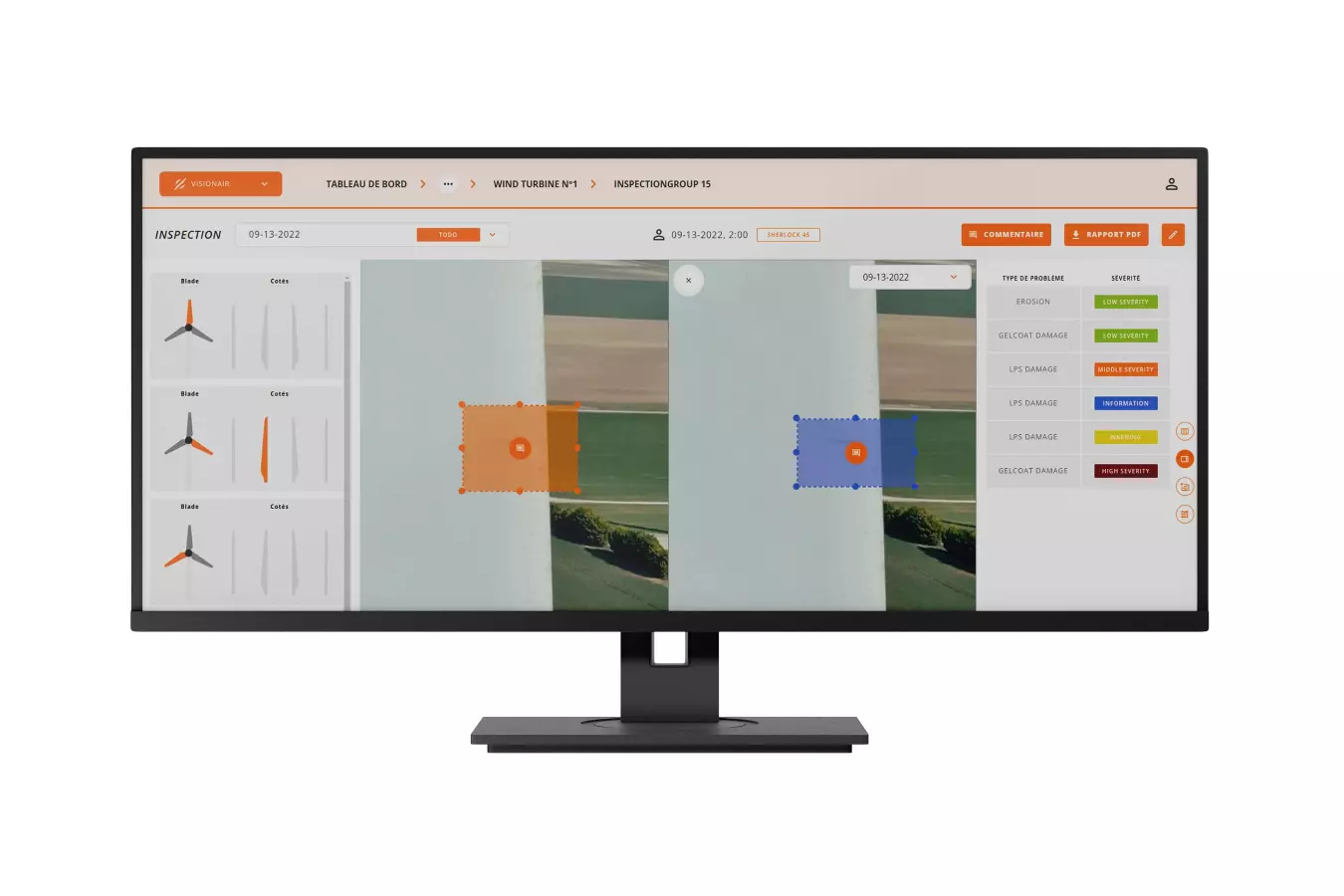

ANNOTATION SYSTEM

PRE/POST INTERVENTION REPORTS

On VisionAir, you have all the necessary tools to evaluate precisely the irregularities and defects of your blades and towers. It is an ideal device to conceive your maintenance maps and adjust your schedule thanks to high-quality images (Sherlock+) and a wide range of diagnosis (Sherlock, Volta, Clarity): picture-based inspections, diagnosis of the lightning paths, thermographic inspections.

Improve your operational excellence and intervene quickly in case of routine inspections or for emergency inspections due to an accident (storm, lightning strike, blade breakage, fire, etc.).

- Precise indication of the type of defect, its size and localisation (as well as its depth in case of an active thermography)

- Adapted to all types of inspections: doubt-raising, periodic, regulation, end of guarantee, due diligence, etc.

- Services adapted to all your needs (Sherlock, Volta, Clarity)

- Picture coverage of 100% of the surface of your blades and towers

- Inspection of the 4 sides of the blades and 6 angles of the towers

- Identification of the defects by our SupAirVision experts, assisted by an Artificial Intelligence (AI under development)

HOW IT WORKS?

- Automatic flight and shots

- Transfer of the pictures on our VisionAir cloud

- Assembly of the pictures for a complete and ergonomic view

- Identification of the defects (size, location, criticality) by our experts and AI (under development)

- Annotation on the VisionAir platform

- Generation of customizable reports and integration in your CMMS

ASSOCIATED PRODUCTS:

Benefit from the flexibility of the annotation system developed by SupAirVision to have a clear and exhaustive vision of your turbines (blades and towers). You can have access to a fully digitalised view of the blades and towers for a global vision of your assets on which the defects and anomalies are directly located and annotated.

Discover the annotation-link feature to only make the most flagrant defect appear when the same defects are repeated. It is also possible to use it when the defect might appear on more than one side or even to monitor a defect over time: link the annotation to a previous inspection and visualise its evolution.

The defects are registered by our independents blade and composite experts, based on a customizable defect grid, which annotates and affects a severity rating. We remain in charge of the defects’ annotation in order to adapt the SupAirVision diagnosis to your needs. You can also have a total control over the detection and characterisation of the anomalies and defects, by annotating them autonomously.

- Exhaustive cartography of your asset

- Complete reconstruction of the blade

- Annotation 50% faster than on a photo gallery thanks to the stitching feature

- Annotations by our blades and towers experts, or autonomously by your teams

- Annotation-links: repetition of defects, defect on various shots, monitoring of the defects over time

- Customizable defect grid according to your requirements

HOW IT WORKS ?

- Availability of the assembly on VisionAir

- Defects stored in our annotation system, by our expert or directly by your teams

- Reports generated automatically and adapted to your need of the moment

- Data stored via the history of the inspection to facilitate the monitoring of the defects in time

ASSOCIATED PRODUCTS:

With VisionAir, take advantage of the automatic generation of inspection reports, with an historic of the inspection, the monitoring of the defects, the publication of a before/after repair in white label.

Edit efficient and useful reports thanks to our personalised filters: selection by type of defects and irregularities, by severity, etc.

- Automatic generation of reports

- Possibility to mask low severity defects

- Possibility to conceal certain recurrent defects to make only the most severe appear

- Link the defects from one inspection to another

- Reports edited by our blades and towers experts

- Position, size and localisation of the defect indicated to predict repairs

- Filter the defects to appear on the report

- Possibility to edit the reports in white labels

- Aggregate in the same place the data of several inspections for an efficient monitoring of the anomalies

- Reports that can be used as justification for control bodies

HOW IT WORKS ?

- Realisation of the intervention

- Pre and post-repairs data entered on VisionAir platform

- Annotation of the defects by our experts or your teams

- Link between the defects (pre-linking AI under development)

- Selection of the report’s filters

- Automatic generation of the report

- Display of the report with the general description of the turbine and the selected defects

- Efficient planification of the repairs

ASSOCIATED PRODUCTS:

INTERNALISE OUR SOLUTIONS

SupAirVision is adapted to your needs with its personalised offers and enables you to internalise its visual inspection tools, by manual or automatic flight, and diagnosis of lightning paths (by assisted flight) thanks to our renting offers. Benefit from a complete training to take charge of the adapted protocols: simulator, technical and practical training, to safely pilot the device and obtain quality data. Discover the simplicity of our flight applications and become completely autonomous for the inspection of your turbines!