Assets Management

ASSETS MANAGEMENT

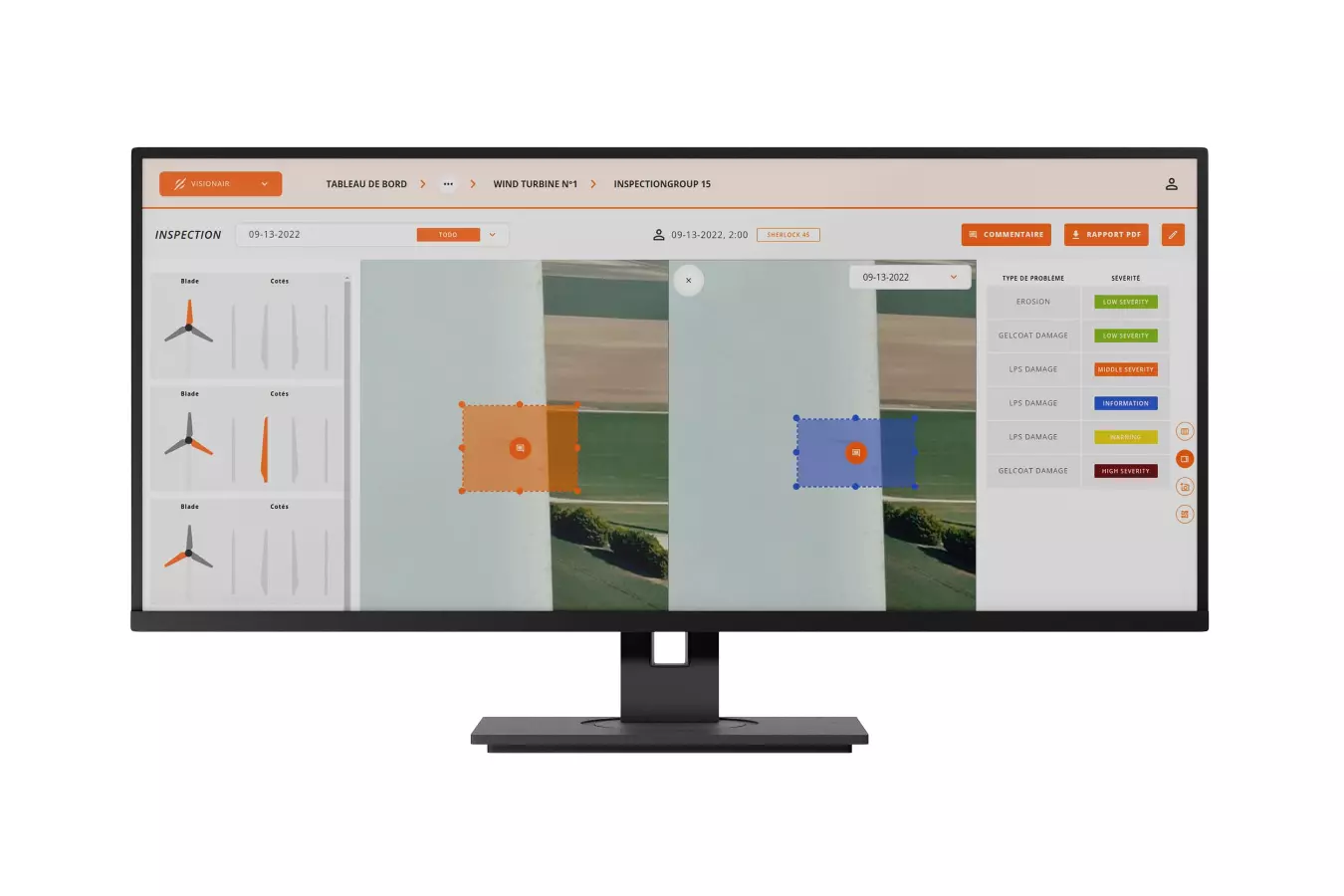

Benefit from the most innovative and performing tools for the management of your wind turbines assets. The reduced downtime, the safety of your teams and the quality of the reports enables you to lead an optimised monitoring of your operating wind turbines and to better plan the maintenance of your blades. Thanks to the stitching of the inspection pictures and the follow-up of the defects on the VisionAir cloud, keep a detailed and precise record of the state of your operating blades.

RELIABLE

ACCESSIBLE

STANDARDIZED

OUR SOLUTIONS

COMPLETE DIGITALISATION OF THE BLADE AND TOWER

PERSONALISED REPORTS

IS/CMMS INTEGRATION

By combining the exhaustive gathering of the information with the digital treatment of your data, SupAirVision tools enable the complete digitalisation of your operating blades and towers:

- Picture coverage of 100% of the surface of your blades and towers

- Assisted and automated flight, a few meters from the blade

- High-quality pictures

- Quick intervention and reduction of the downtime

- Automatic assembly by machine learning

- Precise detection of anomalies and defects by SupAirVision experts, assisted by AI (artificial intelligence under development)

- Generation of automatic and customizable reports

HOW DOES IT WORK?

- Automatic flight and shots

- Transfer of the pictures to VisionAir

- Assembly of the pictures for a complete and ergonomic view

- Identification of the defects (size, location, criticality)

- Reports available on VisionAir or on your CMMS thanks to our Application Programming Interface (API)

ASSOCIATED PRODUCT

With VisionAir, get access to all your inspection data on a single platform. Your reports are impartial and adapted to your needs: the annotations are done by our experts or your teams, the defects grid is customizable and the reports are available in white labels.

A warning is sent as soon as your report is ready to be read for a better planning of your maintenance. You can thus generate your reports automatically, follow the evolution of your assets and quickly identify the critical defects to be repaired.

- Impartial reports, with annotations by our blade and tower experts

- Annotation of the defects by our experts

- Customizable defects grid

- Reports sent up to 2 weeks after inspections

- Possibility of asking for the reports in white labels

- Follow-up of the previous, on-going and upcoming inspections

- Alarm when the report is complete

HOW DOES IT WORK?

- Selection of the filters to appear in the report

- Generation and consultation of the inspection reports on the VisionAir platform

- Planification of the maintenance according to the criticality of the defects

- Use of the reports during inspections led by inspection bodies

ASSOCIATED PRODUCT

Stop wasting time doing double entry and connect your asset management software to our blade management software, VisionAir. With this tool, your data is directly synchronized: you decide what information you want to upload. Our service fits perfectly into your workflow.

- Use of a tool dedicated to blade inspection, VisionAir

- Adapt VisionAir to your asset management tool through our Application Programming Interface (API)

- Easy recovery of history

- Avoid double entries to save you time

HOW IT WORKS?

- Use of global asset management software (example: SAP or ServiceNow)

- Use VisionAir as a blade management tool

- Connector developed between the two applications by SupAirVision

- VisionAir data uploaded directly to your CMMS according to your needs