Clarity

THERMAL INSPECTION

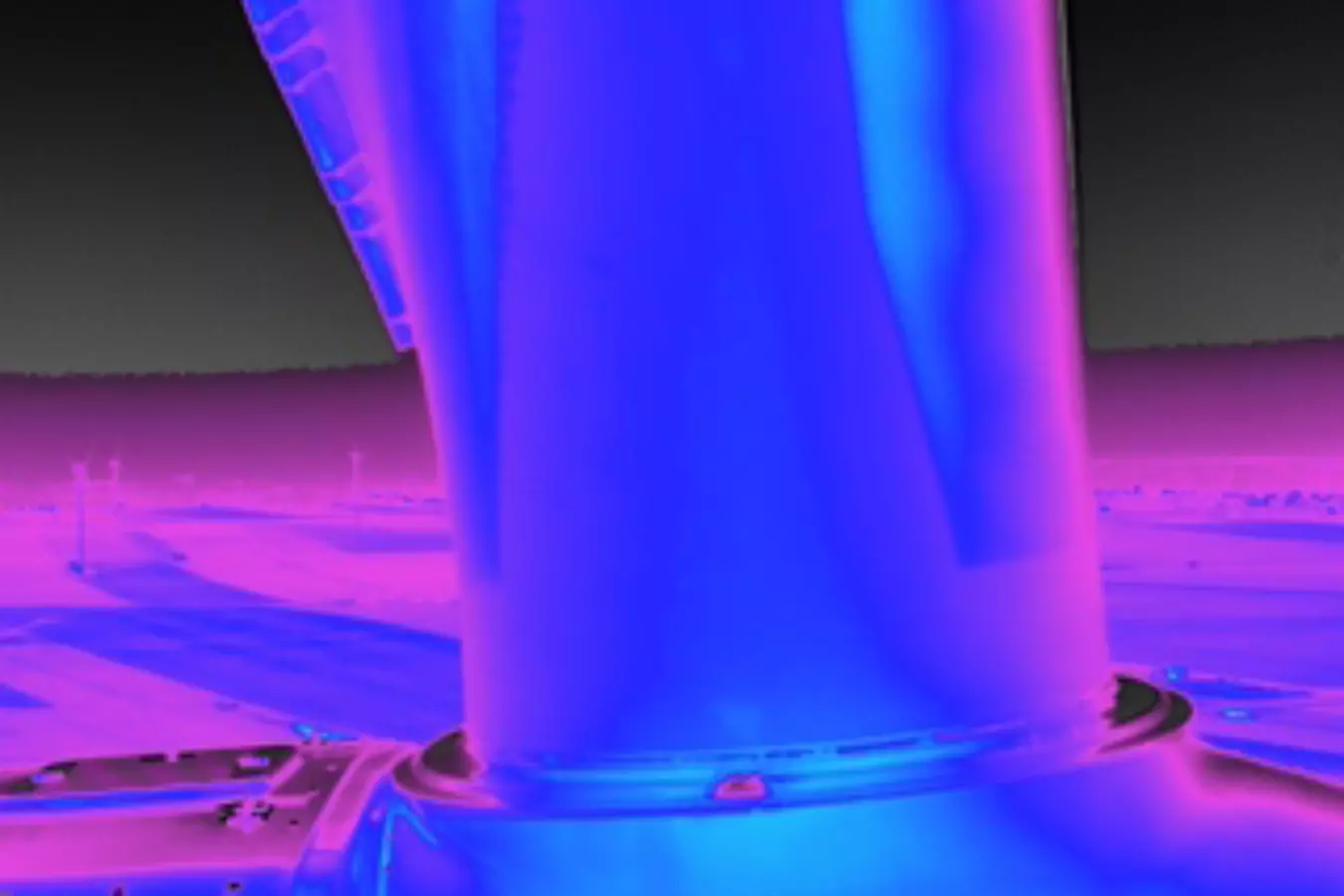

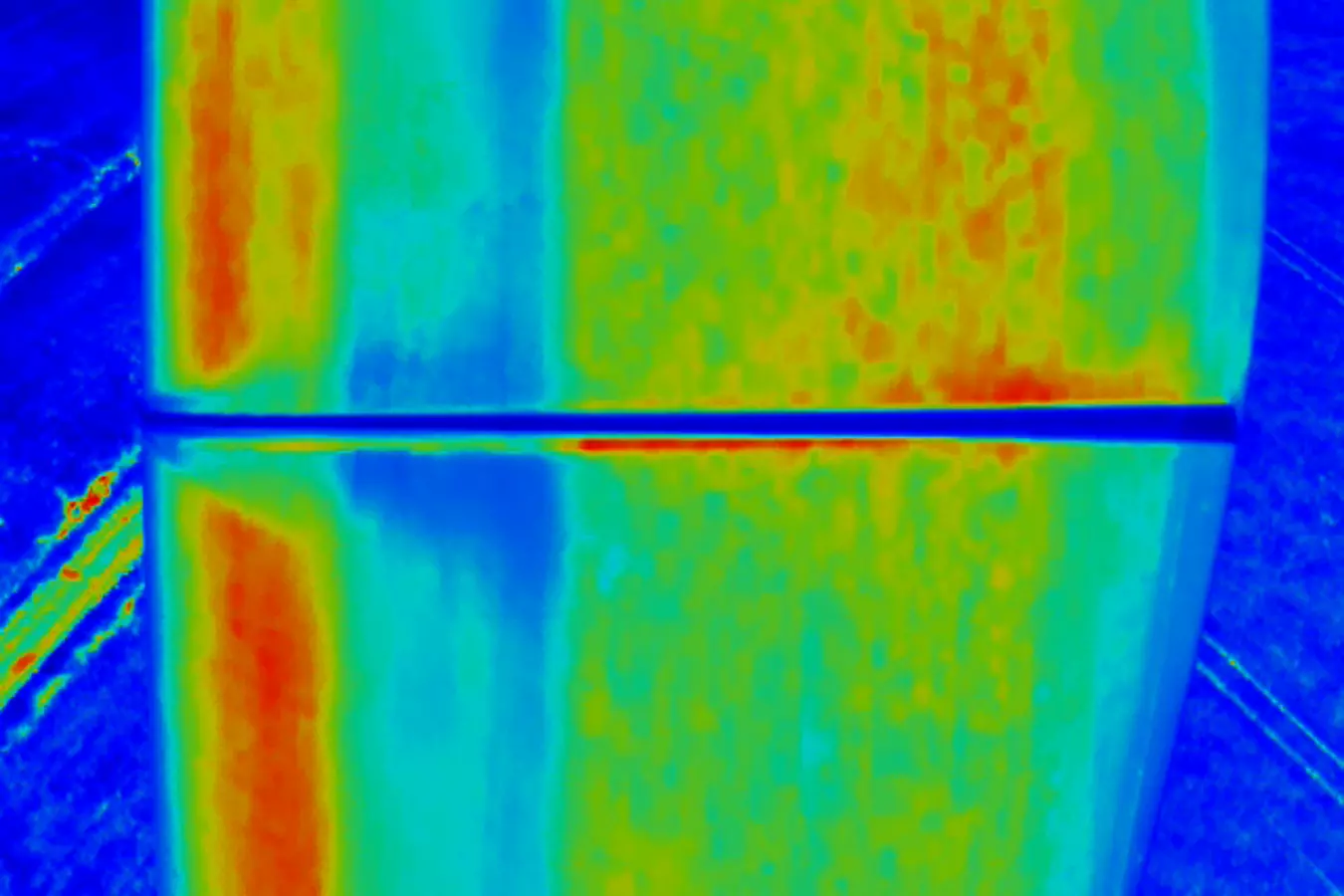

Secure your blades with an internal view by thermography which enables the detection of damages before their spread on the surface. The earlier a damage is detected, the cheaper it is to repair! Our R&D teams use two types of thermography: a passive type which only uses the sun as heat source, and an active one which uses a laser to control the heating of the blade and analyse the thermal contrast. Clarity contributes to the implementation of a preventive maintenance that goes beyond a simple surface inspection of your blades.

CLARITY PASSIF

BENEFITS

GUARANTEED AVAILABILITY RATE

Limit the risks of severe breakdowns to guarantee a high availability of your wind turbine over time: anticipate the repairs by detecting them as early as possible.

REDUCTION OF REPAIR COSTS

Detect the damages in advance to divide by two your potential repairs cost. The two sides (PS and SS) of your blades are inspected simultaneously by thermography and visual picture-taking in order to not miss any of the potential damages.

MATERIAL AND OPERATION SECURITY

Guarantee the security of the technicians and the wind turbine by closely following the evolution of the internal damages before their propagation to the surface or the breaking of a blade.

OPERATIONAL EXCELLENCE

Obtain a precise indication of the size and location of the internal damages before their repair to maintain your wind turbines. Our drone pilots and wind turbine technicians will take care of everything.

CLARITY ACTIF

BENEFITS

INDEPTH-DETECTION

In addition to the localisation and size of the identified damage, get a precise and reliable indication of the type of defect and the amount of layers concerned to know its criticality and adapt your maintenance accordingly.

EASE OF USE

Opt for the Clarity system and facilitate the work of your technicians: no cleaning or product required for use, the technology is used with a lifting platform or a blade placed on the ground.

OPERATIONAL OPTIMISATION

Improve your planning by getting precise data of the defect to be repaired to anticipate the time and cost of the repairs. Adjust your maintenance choice depending on our expert’s analysis.

INNOVATIVE TECHNOLOGY

Discover the only patented solution for detecting internal damages by active thermography, capable of providing you reliable data.

SAFETY

RELIABILITY

INNOVATION

IN PICTURES

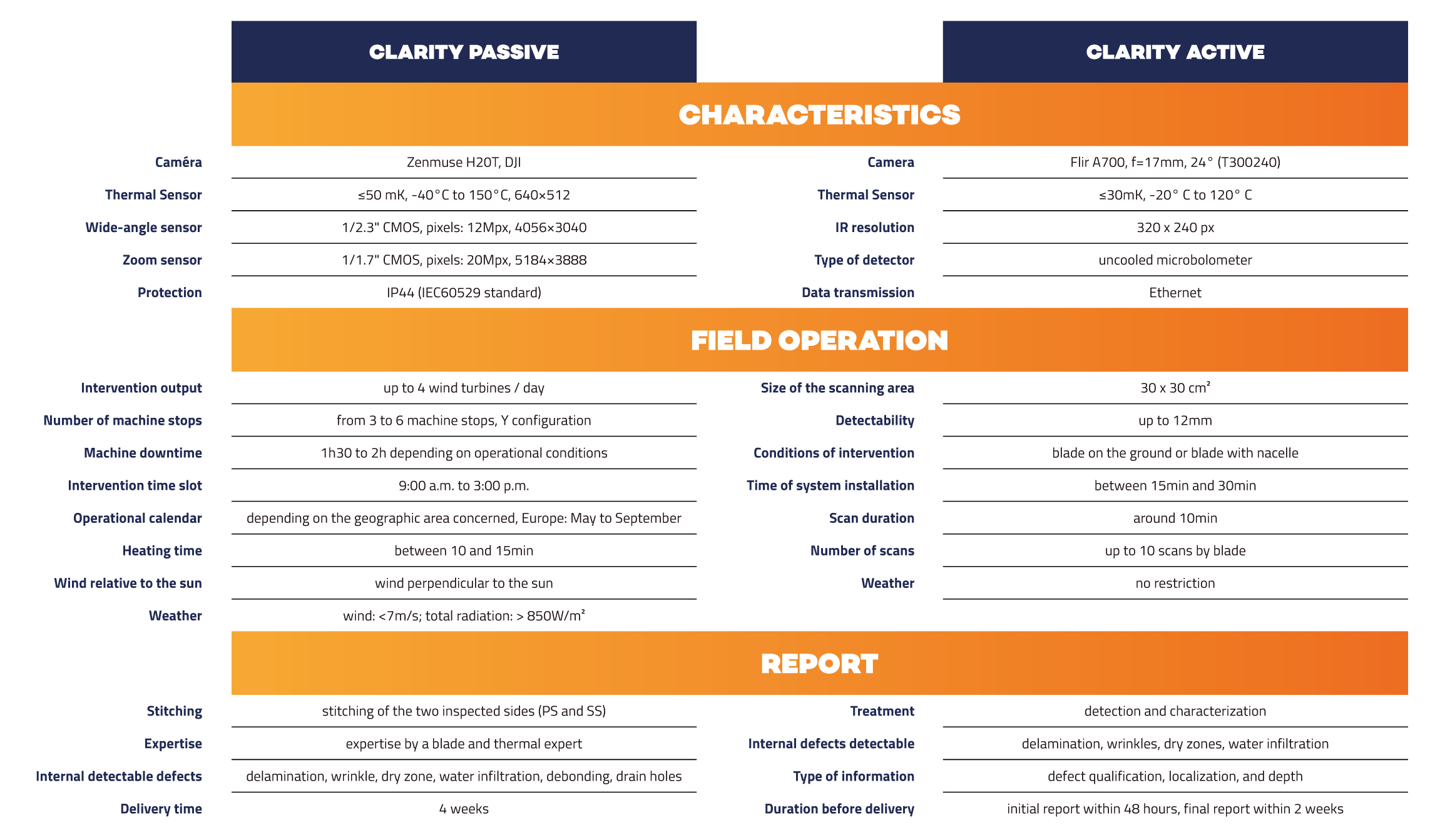

TECHNICAL SHEET